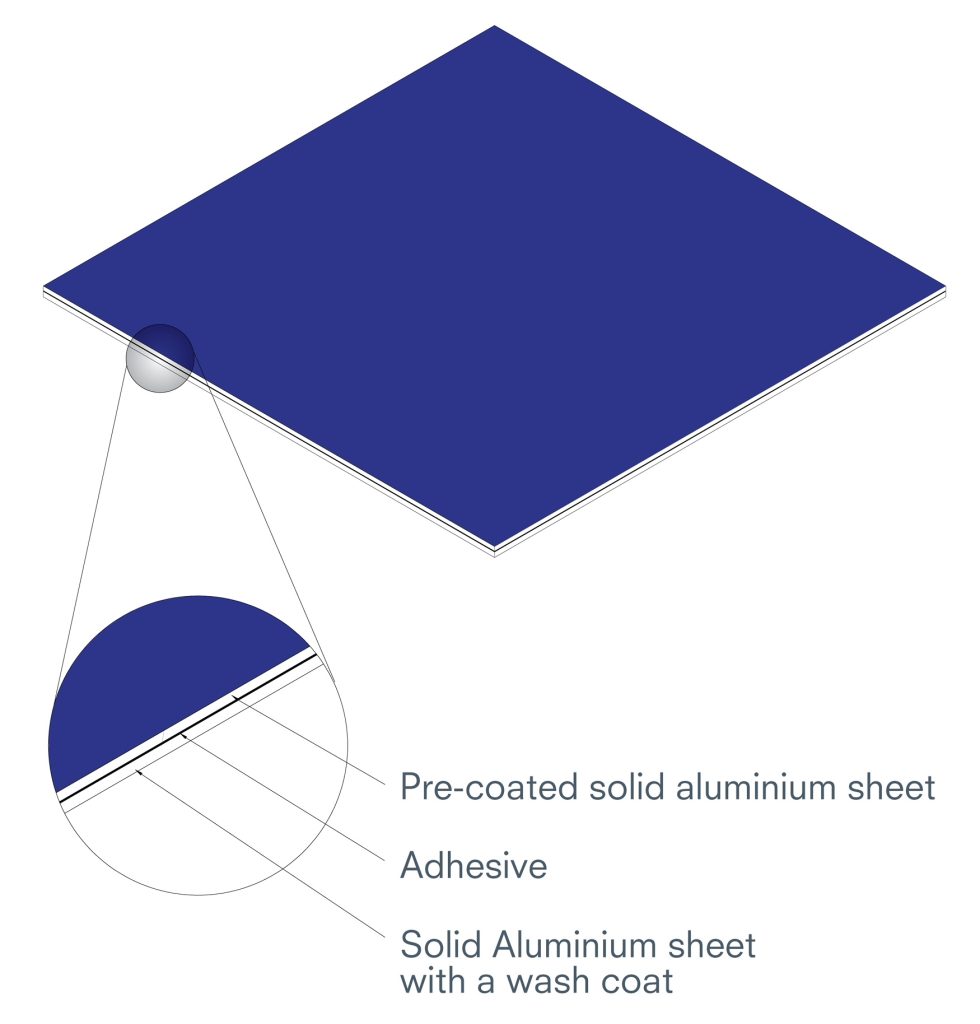

3A Composites, a Swiss-based global leader in Aluminium Composite Materials, introduced ALUCODUAL® through its flagship brand ALUCOBOND®, expanding its portfolio of cutting-edge cladding solutions. ALUCODUAL®’ is the latest offering from the Company for the usage in architectural applications where design and performance play a crucial role. Completely researched, designed, developed and manufactured in 3A Composites’ state-of-the-art plant in Ranjangaon near Maharashtra’s Pune in India, ALUCODUAL® is a pre-coated engineered solid sheet with the layers of laminated aluminium skins, which has multi-purpose applications for facades, cladding and curtain walls, interior walls, ceilings, soffits and column decoration.

Analysing the cladding needs, usage and specifications from the architectural point of view, ALUCODUAL® has been designed to deliver the most prominent feature of ‘perfect flatness’, which is generally challenging to achieve with standard post – coated solid sheets. Moreover, compared to a single sheet of aluminium of same thickness, ALUCODUAL® panels offer enhanced stiffness and rigidity. This structural stability allows the product being used in larger cassettes and panels, effectively reducing the number of joints and overall costs. The product has been engineered to suit multiple and complex ‘on-site’ cladding application

requirements. The corrosion – free Marine Grade Alloy of ALUCODUAL® ensures the product’s long-term durability.

Ranjeet Sharma, President and CEO, 3A Composites India Private Limited said, “Our latest innovation ALUCODUAL® is an indigenously researched and developed ‘Make-in-India’ product, which is now ready to be rolled out in India and globally. ALUCODUAL® will facilitate architects in designing mega structures with slender, rigid, yet highly formable cladding material, enabling innovative and bold architectural expressions while maintaining structural integrity. This will bring a new wave of designing and application trend in projects such as airports, shopping malls, stadiums, high-rise commercial and residential buildings, etc. We are making our India manufacturing facility a global hub to supply ALUCODUAL® worldwide, especially to Asia-Pacific and the Middle – East countries.”

Amar Kirale, Associate Vice President – Marketing, 3A Composites India Private Limited, said, “The solid aluminium sheet market for architecture in India lacked the presence of organized and branded manufacturers. The architects were always in need of precision pre-coated solid sheets, but they had to settle on hitherto available post – coating solutions. ALUCODUAL® has filled up this gap by introducing pre-coated engineered solid sheets of standard specifications, quality and durability.”

Just like ALUCOBOND®, ALUCODUAL® too undergoes a multi-coat, multi-bake process on a continuous industrial – grade coil coating line utilizing the highest grade of fluorocarbon based PVDF/FEVE paint system as per AAMA 2605 superior performance specification for exterior applications to ensure long-term performance and durability.

ALUCODUAL®, as a product, has a fire-retardant property. The product does not have a thermo-plastic core, hence, it remains inactive in the event of fire, emitting no toxic gases or burning droplets. It is classified as Class A2-s1, d0 according to EN-3501-1 test standards, making it suitable for projects with stringent fire-safety requirements.

The product offers the material’s workability in achieving 3D shapes and complex geometric patterns that makes it highly versatile for various architectural applications. Like other products from the house of 3A Composites, ALUCODUAL® also comes in a range of colours and surface finishes such as standard metallics, solids and vibrant colours, as well as, specialty finishes such as Grove (Wood Look), Anodized Look, Concrete Look, Organics Elegance (Super Glossy Muted Tones) and Colourscapes.

Currently, the Company is targeting architects, developers and fabricators in major markets of India with this new product through its dedicated and well-established sales network.